Tools & Equipment

Working with New Generation Engineered Stone in Australia

CDK Stone Q&A Series:

Working with New Generation Zero Silica Engineered Stone:

What are the Essential Tools and Equipment for the new material?

The emergence of 0% Crystalline silica engineered stone in Australia has changed the stone fabrication industry. Working with this new material requires specific tools and equipment to ensure efficiency, precision, and safety.

Q: Which machine blades perform best on 0% crystalline silica engineered stone?

A: When it comes to cutting the new generation of engineered stone, the Diarex Great White Shark blade is an essential tool. Renowned for its high production capacity and ability to maintain quality cuts throughout its tool life, this blade is well suited to the demands of new generation engineered stone. The advanced composition boasts a special diamond layer with broad application for fast cutting as well as slower feed speed for mitre cutting.

Key Features:

- Specifically designed for the fast production of modern low silica engineered stone.

- Delivers clean, sharp cuts for detailed and intricate work.

Renowned for its high production capacity and ability to maintain quality cuts throughout its tool life.

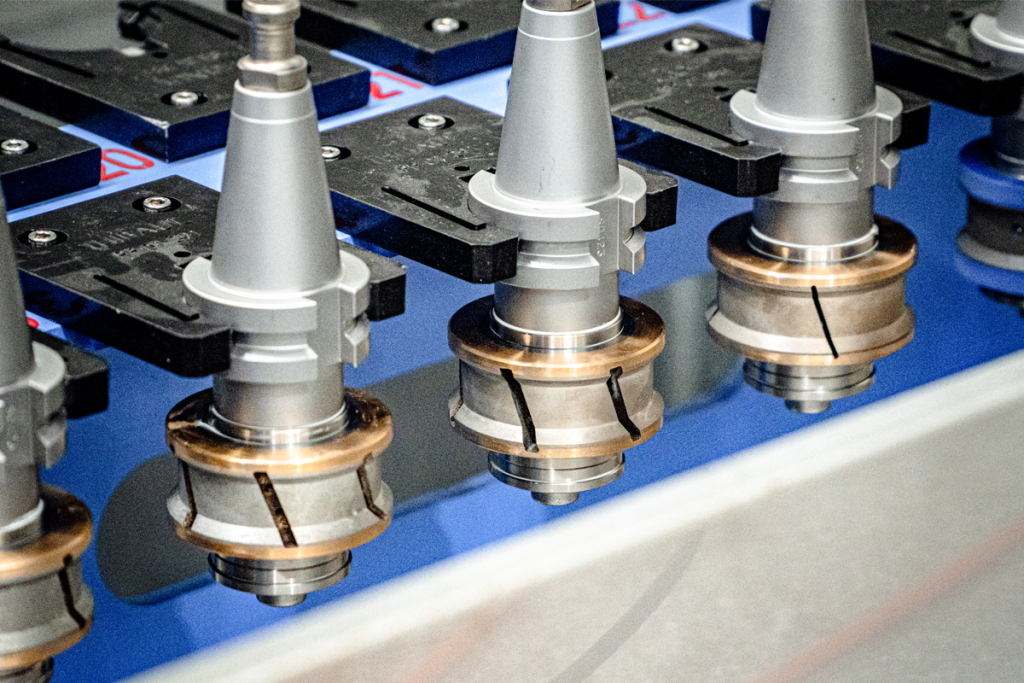

Q: Can you perform clean arris and cut outs on 0% Crystalline silica engineered stone?

A: For CNC machining, ADI CNC tools are the go-to option for professionals working with a range on material types. These tools are specifically designed to withstand the rigors of machining tough materials while maintaining high precision. For machine specific recommendations you can contact CDK Stone for a personalised tool and parameter assessment.

Q: Can you use the same Adhesives on New Generation Engineered Stone?

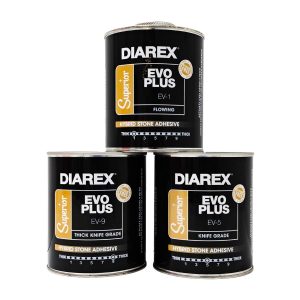

A: When working with new 0% Crystalline silica engineered stone, using adhesives that are specifically designed for engineered stone should be considered. In Australia, there is a diverse range of adhesives, each with unique features to meet the specific requirements of various materials and application styles. Some adhesives with exceptional results on new generation engineered stone include:

Polyester adhesives, like Diarex Poly Plus and Tenax Solid, they set quickly and are cost-effective, making them ideal for New Generation Engineered Stone.

The Integra Adhesives range Rapid, Zero, and Ultra are specifically designed to optimise bonding in stone applications. Each with different benefits that are effective for various applications, including edge bonding and repairs.

EVOPLUS is a new adhesive to the market this new product is the result of combining the trusted expertise of both Diarex and Superior. EVO PLUS, is built on Superior Gold’s world-renowned adhesive technology, ensuring strong, reliable bonds featuring an improved user-friendly mix ratio of 3% – 5%.

When selecting an adhesive, it’s essential to consider the specific requirements of your project, such as setting time, environmental conditions, and the type of engineered stone being used. Consulting with the adhesive manufacturer’s guidelines and performing a small test on a sample piece of the stone can also help ensure the best results.

Q: Why is investing in personal protective equipment (PPE) essential when working with New Generation Engineered Stone?

A: New 0% Crystalline silica engineered stone can become particularly sharp once cut, making the investment in high-quality PPE essential to safeguard against potential injuries. Comprehensive PPE ensures safety and minimises the risk of cuts and abrasions. Additionally, respiratory protection is crucial to be used during the fabrication process. However, it’s important to note that PPE should be the last point of call in the hierarchy of control. All other controllable factors and safe work practices should be addressed first to reduce risks. Please check your state-based WorkSafe regulations on PPE regulations.

Essential PPE:

- Respiratory Protection: CleanSpace and 3M Masks or respirators

Cut-resistant Gloves: PRO have a range of high-grade gloves and sleeves that offer protection against sharp edges and accidental cuts. - Eye Protection: Safety goggles or face shields to protect against flying debris and dust.

The introduction of 0% Crystalline silica engineered stone presents a new alternative for stone fabricators, but it also requires specialised tools and equipment to handle its unique properties. Embracing these tools and safety measures not only enhances productivity but also upholds the highest standards of workplace safety.

CDK Stone provides support for stonemasons who are navigating the complexities of processing the new generation of engineered stone with their unique machinery and factory set-ups. They offer guidance in selecting appropriate tools and adjusting machine settings, ensuring an effective approach to engineered stone processing.