Machinery, Tools & Equipment

A Safer Stonemasonry Future

Have you read the latest issue of Supplier Magazine?

Featured in this months issue are CDK Stone’s range of water processing machines. Read the full article below on how embracing water processing and automation is creating space for a safer stonemasonry future.

A Safer Stonemasonry Future: Embracing Water Processing and Automation

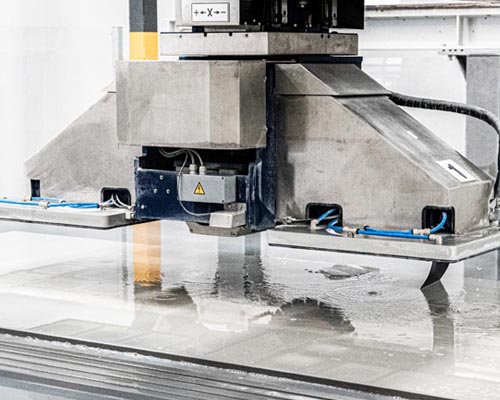

In the active work of stonemasonry, the strategic integration of water processing and automation is pioneering a new age of safety and efficiency. With specialised machinery such as the Dal Prete water treatment system, Extra 480 CNC Bridge Saw, GMM Techni Water Jet, along with offerings from other notable brands like Comandulli, Burkhardt, Thibaut, and Cobalm, businesses can tailor-make production lines that prioritise employee safety while enhancing operational efficiency.

The Essential Role of Water in Stonemasonry

In modern stonemasonry workshops and factories, water plays an indispensable role across various stages of stone processing, including cutting, milling, and polishing. Its strategic application has not only revolutionised the industry but also significantly enhanced the safety of stonemasons

Here’s why water is so crucial:

For Cooling the Tool: In stone processing, the temperature of diamond tools can significantly rise, leading to accelerated wear. Water acts as an effective coolant, preventing the tools from overheating and extending their lifespan. Importantly, this also reduces the risk of accidents from tool malfunction, promoting a safer environment for stonemasons.

For Removing Particles: Stone processing inevitably generates dust and particles. Water aids in removing these particles from the surface, reducing friction with the tool and ensuring a smoother, safer processing operation. By limiting dust production, water also contributes to a healthier workspace, reducing airborne particles.

For Cooling the Surface: Elevated temperatures can detrimentally impact the quality of the stone being processed, which could compromise safety. Water not only helps maintain the stone’s integrity by cooling the surface but also enables the cutting of more fragile materials with ease and efficiency. This ensures a high-quality finish and creates safer conditions for stonemasons.

The Integration of Automation and Water Processing: A Safer Future

By bringing together specialised machinery, each with its unique strengths, businesses can create a production line that significantly improves safety and efficiency. For example, the Extra 480 CNC Bridge Saw ensures accurate and neat cuts while operating in water. The GMM Techni Water Jet enables safe and intricate crafting by submerging the stone and water jetting out a desired shape, making it suitable for tasks like sink hole cuts. Then Comandulli Musa can polish the edges to achieve the desired finish, all while capturing and filtering the water back into Dal Prete’s water treatment system. This ensures sustainable water recycling and contributes to a cleaner environment for employees while saving the expense of additional water.

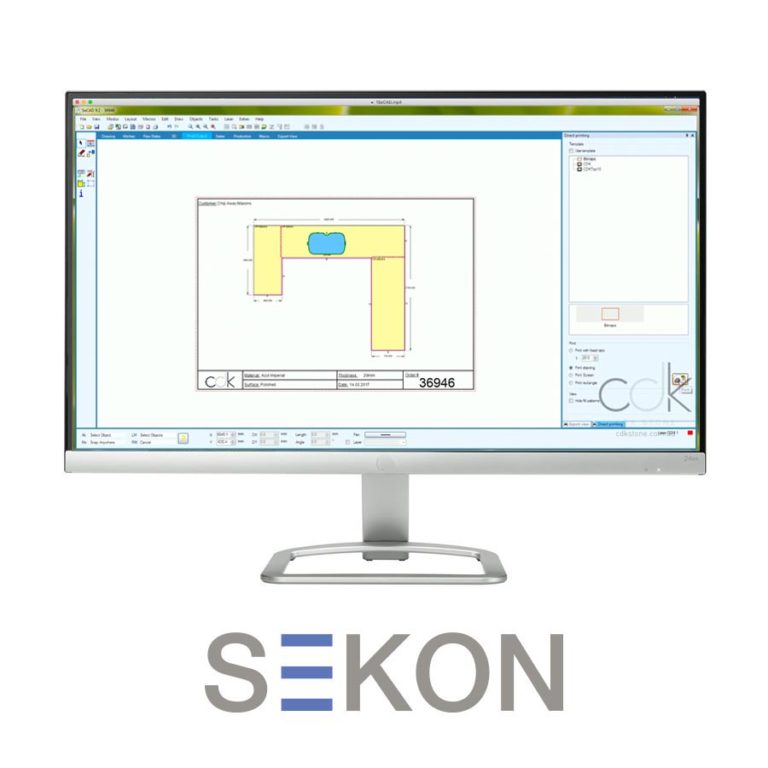

At the heart of this transformation is the SEKON software, which enables the interconnectivity and optimal performance of these machines. It ensures safer and more efficient operations through the automation of processes, reducing the potential for human error and workplace accidents.

By embracing the power of water processing and automation, the stonemasonry industry is pioneering a future where workplace safety and operational efficiency are paramount. This forward-thinking approach results in tailor-made production lines that not only create safer environments for employees but also streamline business operations. As the industry continues to evolve, the central role of water and automation in promoting safety and driving development is becoming increasingly evident.