Machinery, Our Team, Tools & Equipment

CDK Stone’s Fabrication Innovation Day QLD

CDK Stone’s Fabrication Innovation Day Media Release

in Supplier Magazine June 2022

Held on Thursday the 24th of March, CDK Stone’s Fabrication Innovation Day was about educating the industry on the latest advancements and innovative factory practices.

With the current limitations of staffing, factory floor space, time and other resources, many in the stone industry and other related industries are looking for ways to ensure their business is running more efficiently and effectively.

With this in mind, the purpose of CDK Stone’s Fabrication Innovation Day at their Gold Coast warehouse was to educate the local market about the benefits of an automated factory. CDK Stone explored how their range of software and automation products can assist stone processing businesses in maximising their production and planning efficiency.

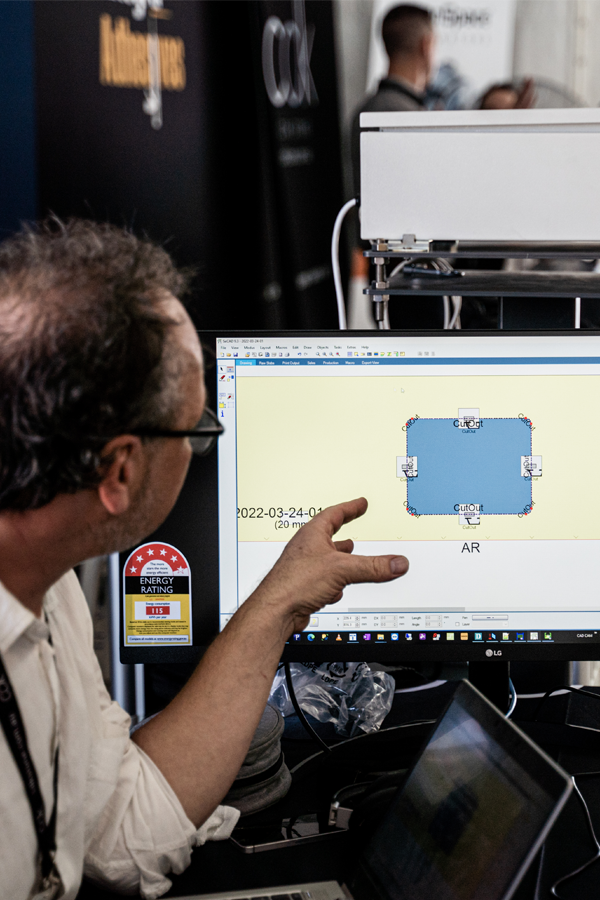

Instead of creating multiple drawings for different machines, Sekon software enables producers to apply just the one drawing to different machines, resulting in considerable time saving and reduced errors. Sekon software enables all the production planning to be managed from an office environment rather than individual operators programming at the machine.

Combined with StonePro business software for inventory, sales, production planning and scheduling visitors on the day were able to appreciate the advantages of linking factory process’s through innovative software,

Both Sekon and StonePro are German software developed especially for the stone industry and have a world wide following. These were demonstrated at the Fabrication Innovation Day in a theatre presentation and on machinery on display, as well as in an adjacent working factory.

Adrian and Marcus Tiso from Absolutely Marble Us in Victoria who were present at the Fabrication Innovation Day gave a live testimonial by demonstrating how the Laser Products LT-2D3D laser templater can measure a job in minutes, and instantly send the completed drawing with edge details and accompanying photographs taken on site directly to the office for preparation of quotes and machine programming. As well as time saved, use of a laser template greatly reduces errors and the need for costly remakes.

Showcasing two of their software solutions, CDK Stone demonstrated how photographing slabs away from the machine using the SeKON software module DigiStat can assist in digital slab book matching as well as management of slab inventory. This innovative process which incorporates a frame with grid references proved of great interest to customers processing natural stone where vein matching is a time consuming and costly process.

CDK Stone also demonstrated their overhead Projection Laser System which can be fitted to new and existing CNC machines using Sekon software. Use of a Projection Laser to position vacuum pods and workpieces on a CNC machine greatly reduces set up time and improves operator safety by reducing worker movements around the machine when setting up.

Software and process’s demonstrated on the day proved of interest to both smaller and larger companies, as the options are modular and can be implemented gradually over time as the company grows and needs change.

As well as showing innovative software and working machines CDK Stone also displayed a range of innovative tools and equipment.

CDK Stone’s Fabrication Innovation Day was a success in educating the market in the latest industry advancements and innovative factory practices, with customers from as far afield as Sydney, Melbourne, Adelaide and Tasmania attending.

CDK Stone will continue to bring their Fabrication Innovation Days to different states around the country, with the next event planned for Sydney in August.

CDK Stone’s Joint Managing Director Jonathan Height said, “Our aim is to educate our industry on emerging innovations and advancements, as well as, highlight the benefits on an automated factory that is run from the office.”“Our Fabrication Innovation Day in Gold Coast succeed in educating customers on how to improve their business in this fast growing market.”

CDK Stone’s Commercial Manager Machinery Peter Mitchelhill said,“Our customers who move to an automated factory run from the office enjoy increased production and an increased output from the same factory as the decision making has moved from the factory floor to the office.” “With many of our customers experiencing limits on staff, factory space and time, we are seeing a positive shift in businesses’ turning towards automation and software to drive a factory’s results.”

CDK Stone’s General Manager, Tooling & Equipment James Clark said, “We are constantly working with our customers to increase their efficiency with the latest tools available.” “The Laser LT-2D3D allows customers to save lots of time templating a kitchen by using laser measuring over traditional manual measuring. The Laser LT-2D3D also allows for easy transferring of templates to software and machinery, as well as, aiding in customer sign offs.”